In 2016, PAREX launched industrial safety prevention campaigns with an emphasis in eye care, same-level falls, hand care, work at great heights, and chemical risk, such as Globally Harmonized System (GHS), Behavior-Based Safety (BBS) and SOS cards. Process Safety, Operational Discipline, and Critical Tasks have also been implemented.

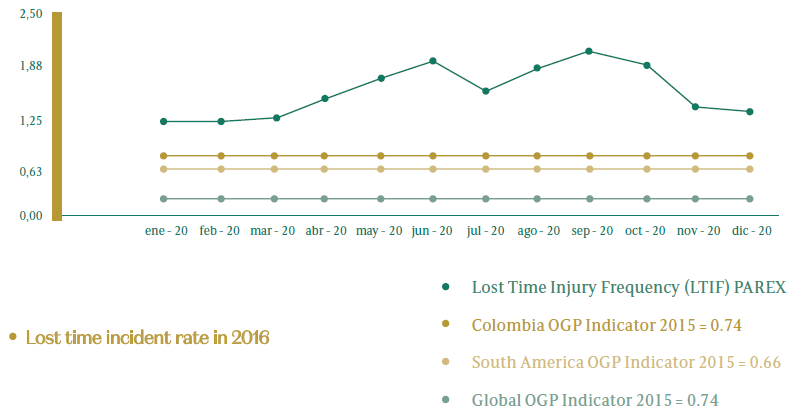

The lost time injury frequency during this period was 1.33, based on a total of 5,257,103 worked hours.

The Company has conducted industrial hygiene assessments regarding physical agents (noise and light) and chemical pollution agents and aromatic by-products (benzene, toluene, ethylbenzene, and xylene).

Regarding ergonomics, work stations were inspected, and morbidity surveys were conducted. These activities will be useful for the implementation of illness monitoring systems.

Concerning employee health, the following actions or programs were implemented: a food innocuousness program, submission of monthly reports, medevac, training for use of on Automated External efibrillator (AED), and tobacco and alcohol consumption prevention. Job profile diagrams were updated.

PAREX’ Health and Safety in the Workplace System is certified under OHSAS 18000:2007.