PAREX addresses environmental protection in accordance with principles of prevention, control,

mitigation, and responsible use of natural resources, aiming to keep operations clean and in

compliance with environmental legislation.

Environmental Management System: Quality and safety

Efficient operations

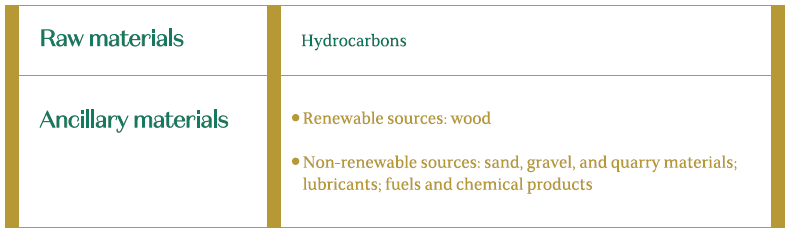

PAREX makes sustainable use of renewable and non-renewable resources when planning operations projects. In 2016, there was a 97% decrease in consumption of sand, gravel, and quarry materials from non-renewable sources, associated with road maintenance and construction of drilling pads. 172,632.56 m³ of these materials were used in 2015 while their use was reduced to 5,169.95 m³ in 2016.

Regarding the use of wood, there was an increase compared to 2015 (118.72 m³), reaching 2,720 m³ in 2016.

As part of the Comprehensive Solid Waste and Materials Management Plan, PAREX returns chemical product packages and packaging to suppliers. In 2016, through third parties, 689 fifty-five-gallon metal trash bins and 4,852 fifty-five-gallon plastic trash bins were reused.

Caring for water, caring for life

PAREX is committed to the efficient use of water by actively protecting water sources and implementing good water use practices. Our practices comply with environmental regulations and always prioritize a non-impact policy for the water supply on local communities.

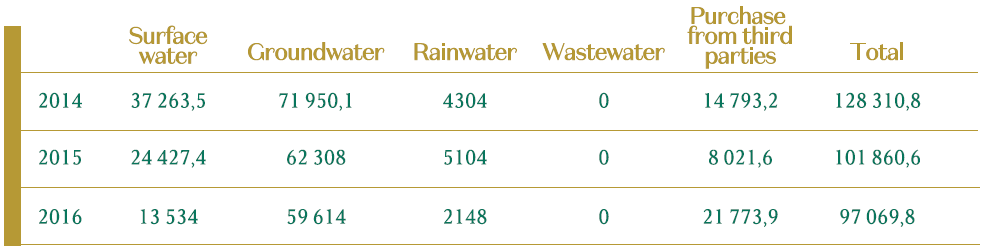

To ensure water management and balance of the ecosystems, the Company constantly monitors water sources. In 2016, we reduced water consumption by 4.7% and the use of collection points by 20%, due to roads paving and the reduction of spraying water on roads.

97,069 m³ of water were used for residential and industrial activities. Average water consumption went from 0.015 m³ per barrel in 2014 to 0.019 m³ per barrel in 2016 due to a decrease in oil production.

With respect to purchasing water for consumption from third parties, all companies have a water concession or authorization issued by the competent authorities.

Surface water sources include the Cusiana and Cabuyarito rivers. According to monitoring activities in 2016, surface water sources did not show changes in their availability and quality conditions associated with the authorized use of operations equipment. With respect to groundwater, in 2016 PAREX collected water from nine deep wells located in Llanos 32, Llanos 16, Llanos 40, and Llanos 30 Blocks. The Company also conducted monitoring activities, which reported no changes in water conditions.

Groundwater 61%

Surfacewater 32%

Pruchase from third parties 13%

Rainwater 2%

Water collection by source in 2016 (%)

Four times more recycled water

In 2016, 0.75% of the total amount of collected water was reused. Approximately 725 m3 of this water was reused, compared to 151 m3 in 2015, showing an increase of 380%.

Regarding formation water, PAREX controls and conducts follow-ups according to environmental regulations and legislation. We conduct regular sampling that helps verify physical and chemical treatments, as well as disposal processes through the re-injection of 28,439,350 barrels in 2016.

Responsible energy consumption

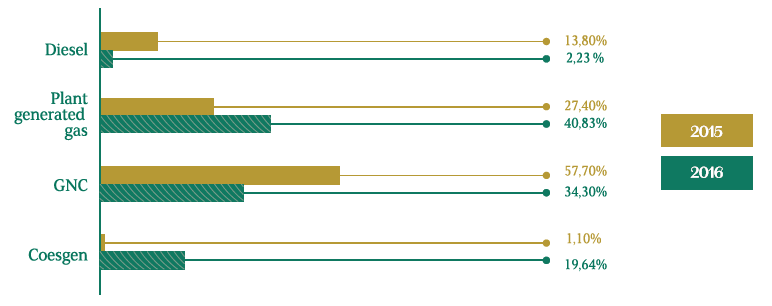

Electrical power consumption reached 15.32 kWh per produced barrel in 2016, an increase from the rate of 12.13 kWh per produced barrel in 2015. Energy intensity in 2016 was 0.64 kW/boe, higher than the 0.33 kW/boe value reported in 2015. This increase was due to a lower production rate in similar operating conditions to 2014.

PAREX uses different energy sources to meet the Company’s needs, including diesel, plant-generated gas, compressed natural gas (CNG), and COESGEN. Regarding energy consumption percentages by source, there was a considerable reduction in diesel consumption compared to 2015 that was offset by the increase in plant-generated gas consumption (self-generation) and in COESGEN consumption.

Zero wastewater discharge

In 2016, the Company maintained its zero-discharge commitment. Water from producing operations that has completed its reutilization cycle is treated to remove solids, oils, and potential oil residues. Final disposal is carried out by re-injecting the wastewater into authorized wells, guaranteeing zero discharge into water and soil ecosystems.

Residential, industrial, and production wastewater, which are not re-injected and require treatment before final disposal, are delivered to a third party. The contractor conducts this process effectively and responsibly, following standard procedures that comply with environmental regulations.

Producction (149 272)

Residential (43 300)

Industrial (37 874)

Wastewater Delivered to Third Parties in 2016 (Barrels)

Disposing of hazardous substances

The disposal of hazardous waste and solid waste generated by PAREX’ operations is outsourced to companies holding appropriate permits that provide collection and proper disposal services.

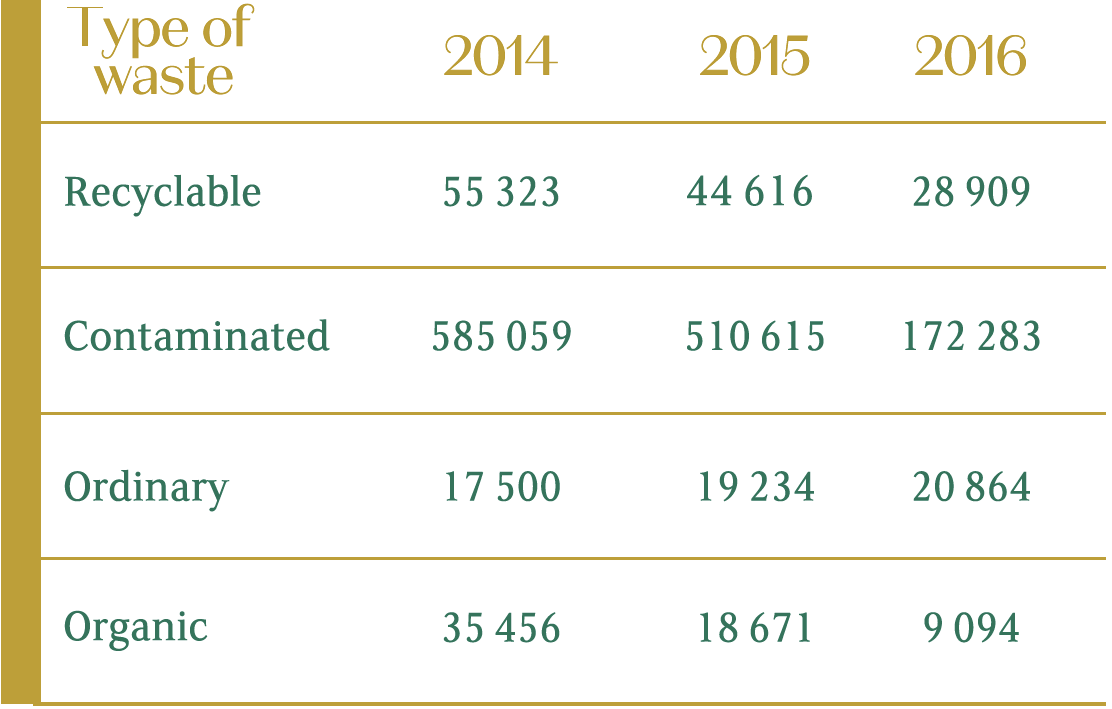

In 2016, recyclable, contaminated, and organic waste was reduced due to environmental management practices promoted by PAREX and reduced operations in certain fields. Ordinary waste volumes increased compared to 2015, caused by cleaning and maintenance of facility areas before terminating operations.

Oil waste generated during production enter the operational system through recirculation, either by adding chemicals or by other means. Other waste, such as chemical product packaging or containers, is returned to suppliers or delivered to companies specialized in treating and recovering these materials. Companies that carry out these activities reuse the materials to bottle the same substances.

PAREX monitors and implements controls for solid waste disposal to ensure compliance with regulations. In 2016, 47,689 barrels of drilling cuttings and sludge were produced, an increase over 2015 that was the result of an increase in drilling activities (17 gross drilled wells in 2016 versus 12 gross drilled wells in 2015). PAREX prohibits the use of benzene and sulfur in its operations.

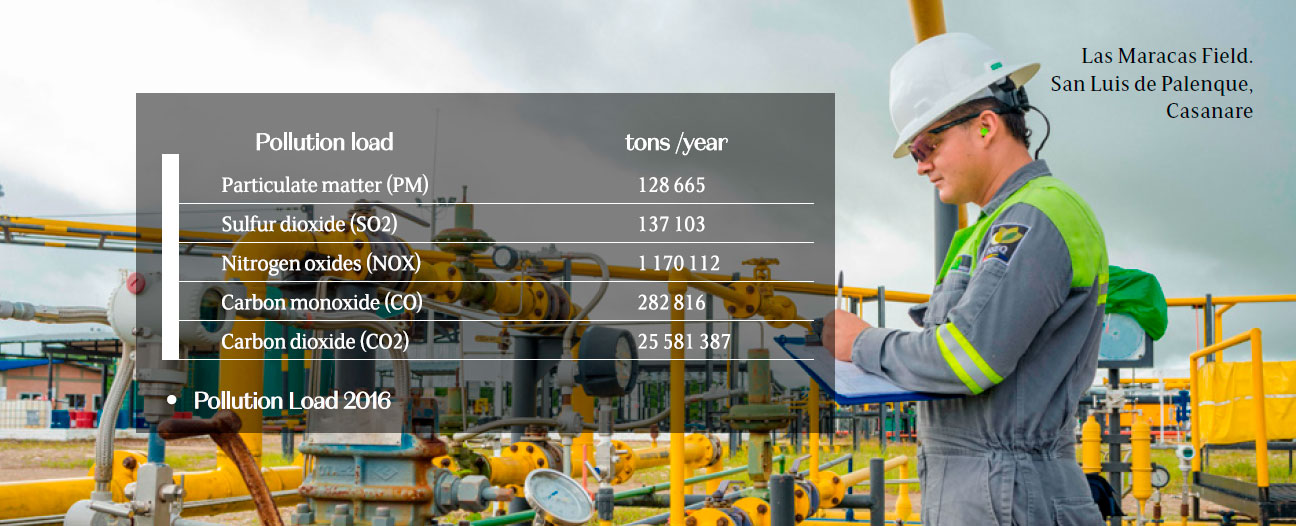

Emissions

Atmospheric emissions generated by PAREX are managed according to the Protocol for the Control and Surveillance of Atmospheric Pollution Caused by Fixed Sources: Version Two (2010), issued by the Colombian Ministry of the Environment and Sustainable Development. Particulate matter, sulfur dioxide, nitrogen oxide, carbon, and carbon dioxide are measured and controlled, in compliance with the National

Environmental Licensing Authority standards for environmental management.

Emission estimations are calculated using emission factor modelling. These estimations are in line with Colombian environmental legislation, according to the specifications of each piece of equipment, including consumption and generation. The Company annually assesses the amount of pollution that can be reduced by implementing good environmental management practices.

Based on 2016 operating conditions, the air pollution load was reduced by 27,300 tons/year by using natural gas instead of diesel in Adalia, Begonia, Kananaskis, Kitaro, Kona, Maracas, Llanos 32 Facility, and Rumba, operations located in the department of Casanare and the Middle Magdalena area.

In 2015, approximately 753 tons/year of pollution load were prevented from entering the atmosphere. In 2016, this value significantly increased.

Based on 2016 operating conditions, the air pollution load was reduced by 27,300 tons/year.

Spills

At PAREX, prevention and management of the risk of environmental accidents that may affect safety are key issues. Preventing crude, chemicals, oils or fuel spills is a permanent undertaking for the protection of the environment and public infrastructure. In 2016, there were 0.7 spilled barrels per million of produced barrels, a decrease from the 1.9 spilled barrels per million of produced barrels in 2015.